CIDETEC Surface Engineering has been working on advanced thermoset polymers and composites based on dynamic chemistry (the so-called 3R technology) since 2014. We have developed tailor-made solutions through joint development projects with companies from a range of sectors, mainly the automotive, wind power, railway and aeronautic industries.

3R composites are a more competitive, sustainable solution in those sectors and applications where epoxy matrix composite materials are used.

We offer:

-

Tailor-made 3R epoxy resin formulations for specific applications and manufacturing processes.

-

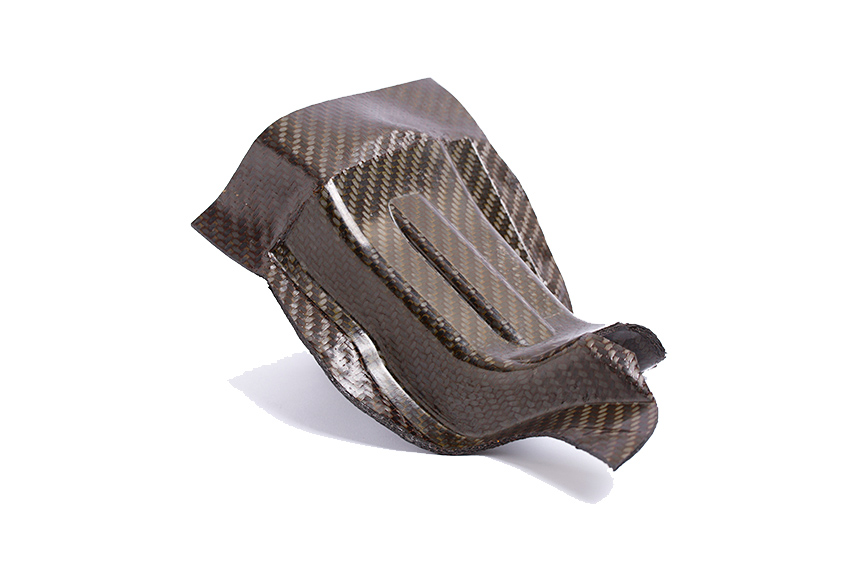

Reprocessing of cured 3R epoxy composites into complex shapes.

-

Fast, cost-effective repairing of delamination damage of 3R composites.

-

Debondable on-command 3R adhesives.

-

Chemical and mechanical recycling paths.