Omniphobic surfaces

Omniphobicity has traditionally been described as the feature of repellency towards all liquids regardless of their surface tension.

Based on this concept, CIDETEC is working on surfaces that repel not only liquids, but also complex substances such as blood, oil and other food and beverage-related stains, along with solid materials such as ice, dust and insects.

Omniphobic surfaces are important because they offer numerous benefits around performance and protection, reduced maintenance cost, high efficiency processes, hygiene and safety, etc. a world to be explored.

Why omniphobic surfaces?

Omniphobic surfaces are typically characterised by very high water and oil contact angles, and can be created in a wide variety of materials. This achieves high repellency towards liquids such as water, oily substances (oil and organic solvents, greases, etc.) and other fluids (moisture in the air, etc.) in a wide variety of applications, resulting in:

- Self/easy-cleaning surfaces

- Anti-stain surfaces

- Anti-icing surfaces

- Anti-fog surfaces

- Anti-soiling surfaces

- Anti-fingerprint surfaces

- Anti-graffiti surfaces

- Anti-bacterial surfaces

- Anti-fouling surfaces

- Anti-insect surfaces

- Reduced drag

What do we offer?

CIDETEC Surface Engineering is committed to providing customised solutions and expertise enabling companies to deal with unaddressed needs in the field of omniphobicity and low adhesion surfaces and coatings.

We develop different chemistries that work both on surface modification (chemical-modified surfaces, polymer-modified surfaces, application of coatings) and on bulk modification, transforming the product from within.

Who is it for?

For the whole coating industry value chain: chemical suppliers, finishing industry, part and component manufacturers, end-users/OEMs.

End users:

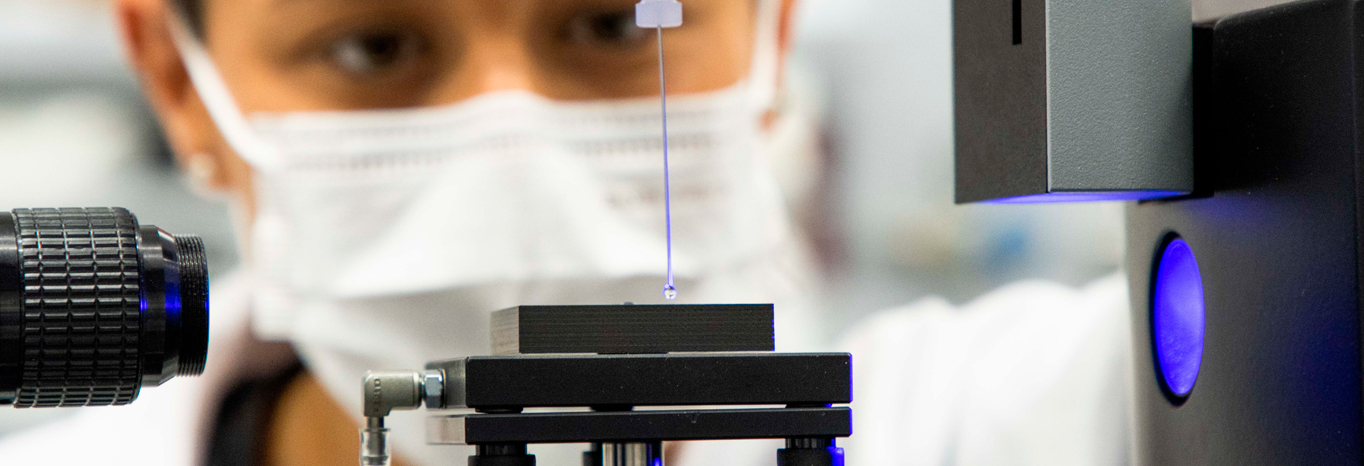

Our capabilities and infrastructure

We develop different chemical strategies to provide surfaces and materials with omniphobic properties adapted to the final conditions of use. We have an interdisciplinary team with strong skills and extensive experience in different industrial sectors, capable of carrying out cutting-edge research focused on different needs. Our fully equipped laboratories and pilot-plant facilities also allow our solutions to be applied and tested in pre-industrial conditions:

- R&D laboratories for the design, synthesis and chemical analysis of formulations.

- Surface preparation and pre-treatment protocols (chemical, physical, mechanical, etc.) adapted to substrate requirements.

- Wet coating application techniques: barcoat, spin-coating, printing techniques (inkjet and screen printing), spray (lab and automated spray system), dip-coating (lab and pilot plant), electrodeposition (lab and pilot plant), etc.

- Thin film characterisation equipment: morphology, composition, structure, aesthetics, wettability, roughness, hardness, scratch resistance and ageing.

Any questions?

For more information please contact us:

More information

"*" indicates required fields

Related Patents

Related Patents Get more information

Get more information Visit our Youtube Channel

Visit our Youtube Channel