Hygienic Surfaces

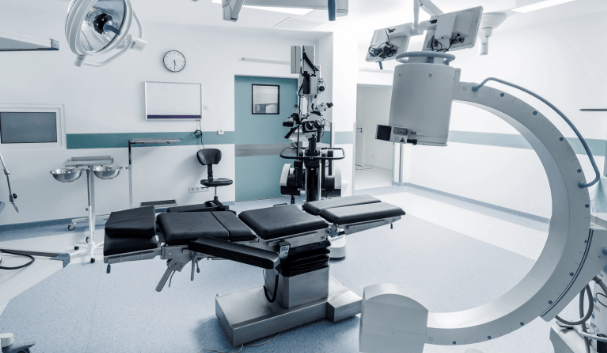

Hygienic surfaces are those that provide ease of cleaning and/or assist in removing or deactivating biocontamination. These surfaces play an important role in maintaining areas with improved cleanliness and restricting the spread of microbiological contamination.

Covid-19 has pushed hygienic surfaces into the spotlight, especially in high-traffic areas, highlighting the real need to provide surfaces that take part in this challenging and most important fight against dirt and hostile microorganisms.

The goal of this demand is to identify novel coatings or surface modifications that readily eliminate or reject contaminants (e.g. bacteria, viruses, toxins, etc.) without intensive external intervention or cleaning.

Why hygienic surfaces?

Hygienic surfaces make it simpler to maintain hygienic areas, and help towards well-being, health and safety thanks to:

Anti-bacterial/anti-microbial and anti-fungus properties

Anti-stain properties

Easy-cleaning properties

Anti-fouling properties

What do we offer?

CIDETEC Surface Engineering is committed to providing customised solutions and expertise to enable companies to deal with unaddressed needs in the field of hygienic surfaces.

We offer key innovation areas with particular focus on hygienic surfaces and materials that are:

We are working on different strategies focused on developing hygienic surfaces based on nanotechnology, coatings and surface modification techniques for a wide range of materials and substrates (e.g. textile, metal, plastic, glass, etc.):

- Omniphobic surfaces

- (Electro)polishing

- Metal and metal matrix composite coatings

- Sol-gel coatings

Who is it for?

For the whole coating industry value chain: chemical suppliers, finishing industry, part and component manufacturers, end-users/OEMs.

End users:

Our capabilities and infrastructure

We develop different chemical strategies to provide surfaces and materials with hygienic properties adapted to the final conditions of use.

We have an interdisciplinary team with strong skills and extensive experience in different industrial sectors, capable of carrying out cutting-edge research focused on different needs.

Our fully equipped laboratories and pilot-plant facilities also allow our solutions to be applied and tested in pre-industrial conditions, including surface preparation and pre-treatment protocols.

- R&D laboratories for the design, synthesis and chemical analysis of formulations.

- Surface preparation and pre-treatment protocols (chemical, physical, mechanical, etc.) adapted to substrate requirements.

- Wet coating application techniques: barcoat, spin-coating, printing techniques (inkjet and screen printing), spray (lab and automated spray system), dip-coating (lab and pilot plant), electrodeposition (lab and pilot plant), etc.

- Thin film characterisation equipment: morphology, composition, structure, aesthetics, wettability, roughness, hardness, scratch resistance and ageing.

Any questions?

For more information please contact us:

More information

"*" indicates required fields

Related Patents

Related Patents Get more information

Get more information Visit our Youtube Channel

Visit our Youtube Channel