The removal of residues accumulated on surfaces and parts during manufacturing processes plays a key role in guaranteeing the quality of the production process.

It has been proven that many faults in the use of components for leading sectors such as the automotive, aeronautics and electronics industries are related to the presence of contamination, which is why quality standards in this area are becoming increasingly more demanding.

Why is it necessary to define a thorough surface cleaning and preparation process?

To ensure a high-quality end product it is necessary to control the surface preparation and the quality of the cleaning of the components:

More than 90% of a coating’s performance depends on correct and careful surface preparation prior to application. If the surface preparation is incorrect or incomplete, even the most technologically advanced coating will fail sooner or later. The aim of surface preparation is to completely remove all contaminants to make it ready to receive the subsequent coating or surface treatment, giving the base material the desired properties.

Removing residues accumulated on parts during the manufacturing processes (machining, stamping, welding, etc.) is a determining factor in guaranteeing the proper execution of the subsequent phases of the production cycle, as well as the storage of the finished part and its final dispatch to the customer.

Controlling the process to guarantee the highest level of cleanliness allows the following:

To determine the source of the dirt

To define the necessary degree of surface cleanliness to avoid problems in subsequent manufacturing processes

To avoid rejects

To achieve Zero Defects

We offer technical solutions to real production problems, quickly diagnosing the problem and providing the optimum solution:

For the manufacturing industry value chain: material processors, finishing industry, component manufacturers, end-users/OEMs.

You name

the next

application

Our Capabilities and Infrastructure

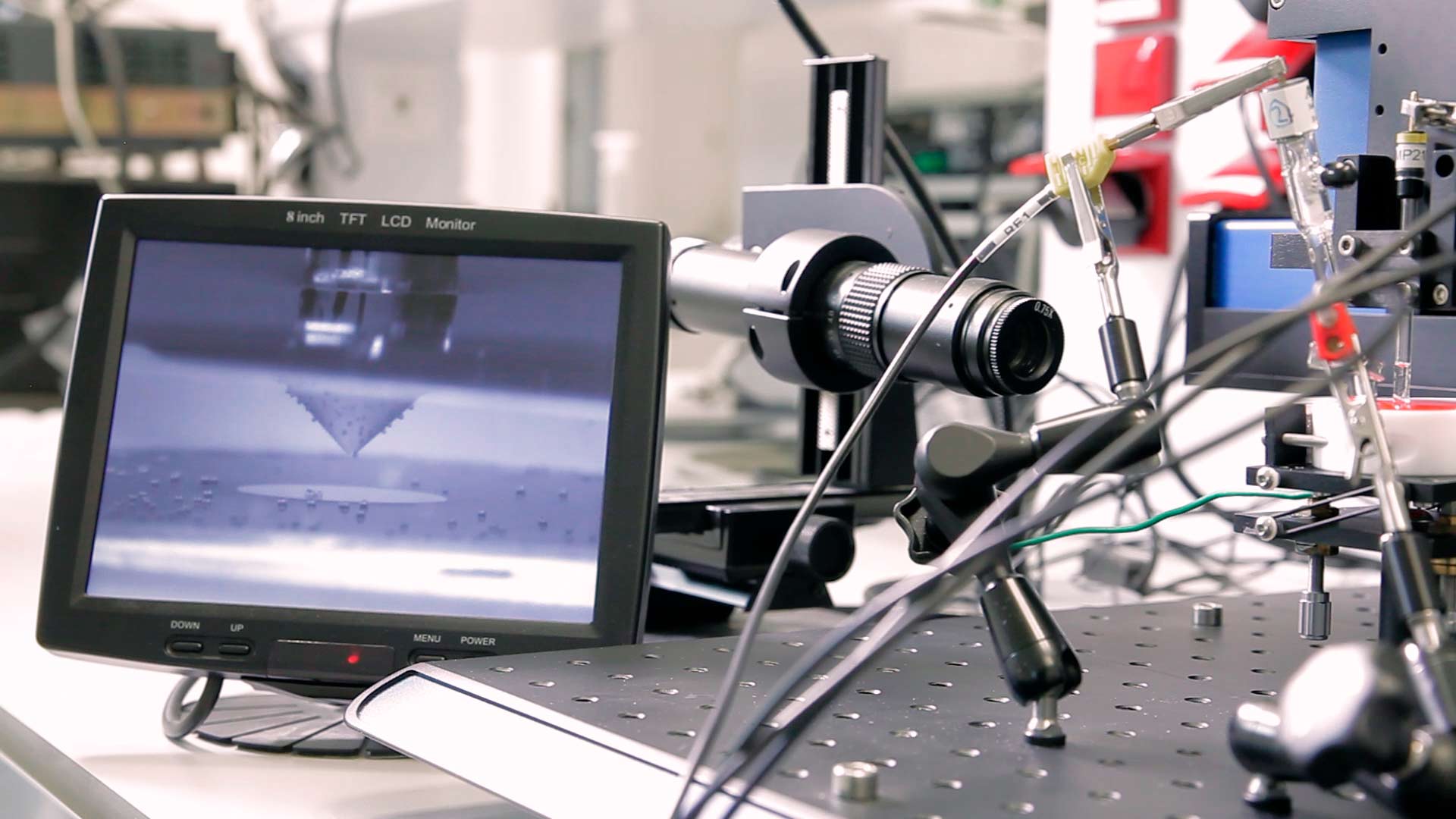

Dirt analysis, characterisation and control laboratories

CIDETEC has equipment to quantify the particle size and characterise the type of dirt, both organic and inorganic:

- ORGANIC from cutting fluids, adhesives, pastes, fluxes, etc.

- INORGANIC from residues of cleaning products, oxides, abrasives, metallic particles, etc.

Our pilot plants allow us to simulate any real industrial processing conditions, enabling us to adapt the results to the most demanding finishing conditions.

- Immersion cleaning

- Mechanical cleaning

- Laser cleaning