SURPASS

The project:

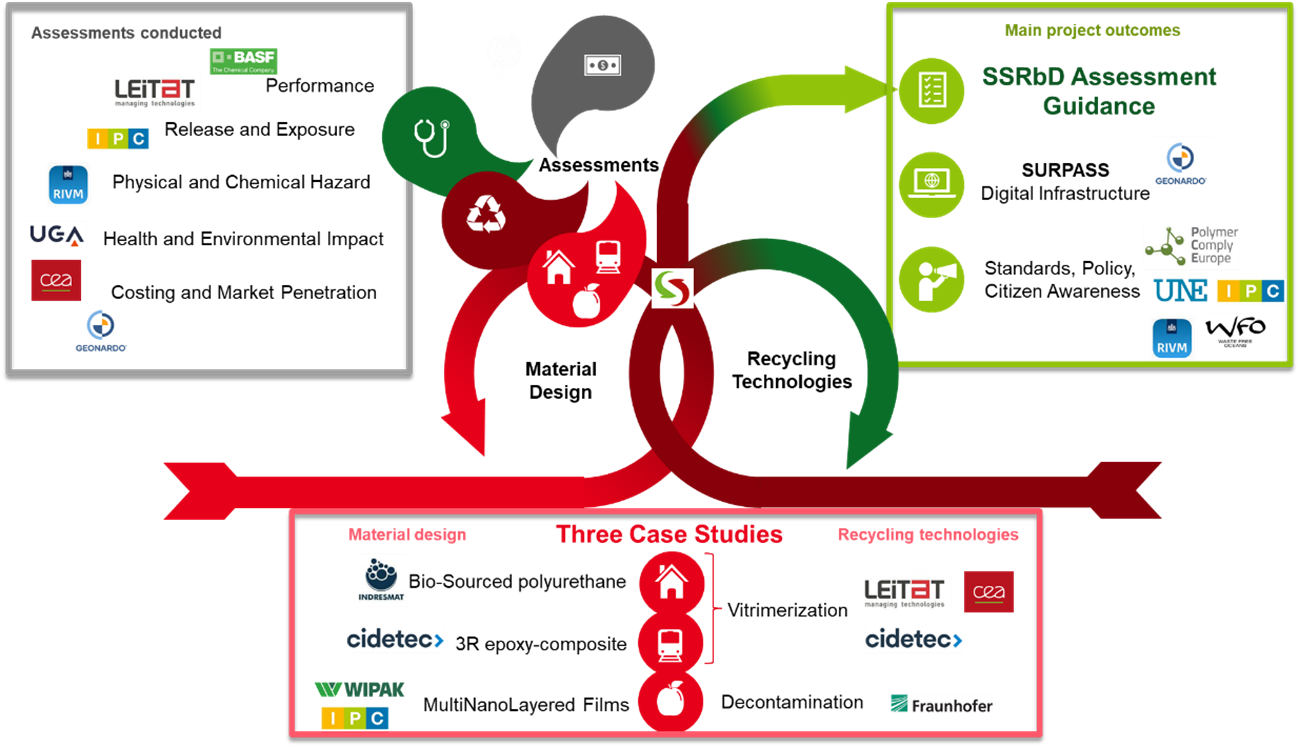

SURPASS is a 42-month project within the Horizon-CL4-2021-Resilience-01 call, whose overall objective is to lead by example the transition to safer, sustainable and recyclable by design (SSRbD) polymeric materials.

Plastic waste is outstripping us on the planet, as it takes centuries to decompose. The danger of endocrine disruption from leached substances, rapid growth and contamination of land, air and water, as well as greenhouse gas emissions, are just some of the adverse effects of plastic waste on public and environmental health. Yet 70% of plastic waste collected in Europe is landfilled or incinerated.

To this end, the SURPASS consortium will:

– Develop SSRbD alternatives without potentially hazardous additives through industrially relevant case studies (TRL3-5) targeting the three sectors (construction, transport and packaging) that account for 70% of the European demand for plastics.

Optimise reprocessing technologies adapted to new SSRbD systems to support the achievement of ambitious recyclability targets.

– Develop a score-based assessment to guide material designers, formulators and recyclers to design SSRbD polymeric materials, which operate throughout the entire life cycle of the plastic, including hazard, health, environmental and economic assessment.

– Bring all relevant data and methodologies together in a digital infrastructure, providing an easily accessible interface for innovators.

The SURPASS consortium, research and technology organizations and industries, will in particular address its results to SMEs, representing more than 99% of enterprises, and therefore has an outstanding potential to contribute to the transition towards green economy.

CIDETEC’S role in the project:

CIDETEC will lead Case Study 2 aimed at the Transport sector, more specifically the railway sector.

Today, composite materials are gradually entering the railway sector, replacing metal parts, thus achieving agility, and reducing energy consumption. Nowadays, reducing emissions and the carbon footprint on the ground is paramount. However, the composites used so far in this sector are not recyclable and this is where CIDETEC Surface Engineering holds the key.

CIDETEC, through the 3R technology and with the help of partners ICT and BASF, will formulate and manufacture recyclable and sustainable epoxy composites that, above all, will show increased fire resistance.

Start: 01 | 06 | 2022

End: 30 | 11 | 2025

Budget: 4.980.560 €

COMMISSARIAT A L ENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES (CEA, French state) (Coordinator)

CENTRE TECHNIQUE INDUSTRIEL DE LA PLASTURGIE ET DES COMPOSITES (IPC, French state)

CIDETEC Surface Engineering (Spanish state)

ACONDICIONAMIENTO TARRASENSE ASSOCIACION (LEITAT, Spanish state)

INDRESMAT SL (Spanish state)

UNIVERSITE GRENOBLE ALPES (UGA, French state)

GEONARDO ENVIRONMENTAL TECHNOLOGIESLTD (GEONARDO LTD, Hungary)

BASF SE (Germany)

RIJKSINSTITUUT VOOR VOLKSGEZONDHEID EN MILIEU (RIVM, The Netherlands)

ASOCIACION ESPANOLA DE NORMALIZACION (UNE, Spanish state)

FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG E.V. (FRAUNHOFER, Germany)

WIPAK CRYSPEERT SAS (WIPAK, French state)

WASTE FREE ONCEANS EUROPE (WFO, Belgium)

Financiator

No hay imágenes en el array de logos financiadores.Sectors

- Railway

Technological fields

- Sustainable Composites