Post-processing of Additive Manufacturing

Additive manufacturing (AM), also known as 3D printing, is a process used to create a digitally defined physical 3D object by accumulative deposition.

This manufacturing process has become particularly relevant as it allows extreme personalisation and complex geometries that cannot be obtained by other traditional manufacturing methods. This is an extraordinary tool that meets the requirements of different sectors such as aerospace, biomedicine or automotive, as it offers the option to build strong, flexible rigid structures that are still light in weight.

Why AM post-processing?

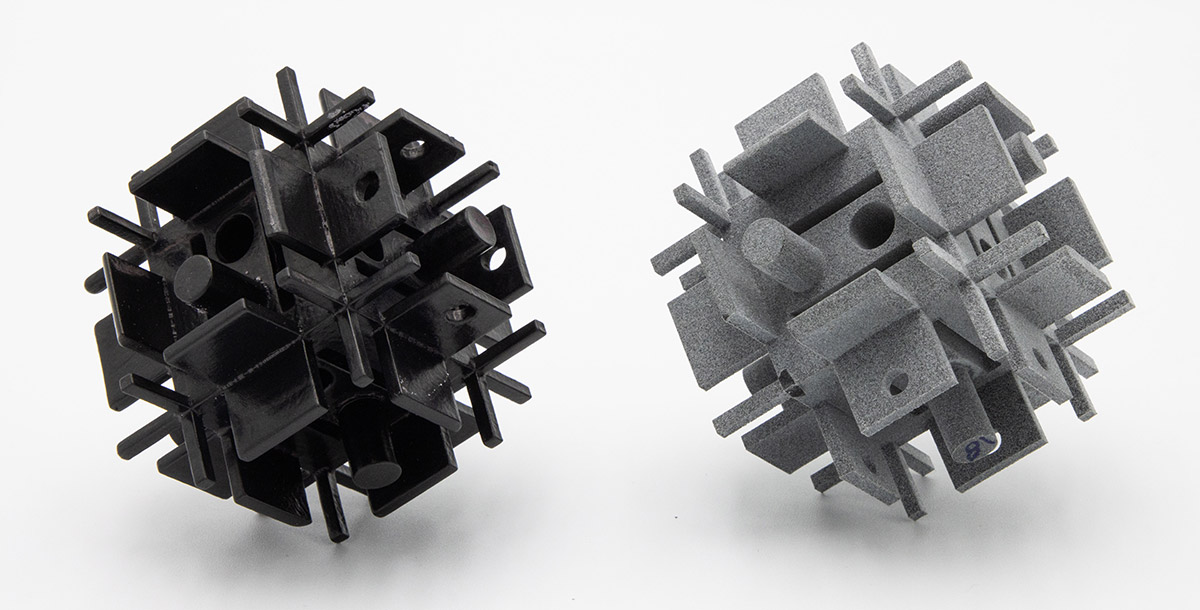

Unfortunately, the AM processing does not finish with printing. 3D printed parts are usually enclosed in structural supports, which are necessary for the complex geometries 3D printing allows. Moreover, 3D printed parts frequently show manufacturing lines and high surface roughness, affecting not only the aesthetics but also several functional properties such as fatigue resistance, frictional properties, and heat transfer.

Surface post-processing is therefore a necessary step in the additive process in order to transform the raw 3D printed parts into high-quality products.

What do we offer?

CIDETEC Surface Engineering is committed to providing customised solutions and expertise, enabling companies to deal with unaddressed needs in the field of metal and polymer AM post-processing.

We develop sustainable processes (physical, mechanical, chemical and electrochemical) for easy removal of supports and reduction of roughness and surface functionalisation, with results that match industry requirements in terms of automation and digitalisation. These processes include removal and finishing processes while meeting the dimensional standards demanded by industry:

Removal processes

- Removal of powder from the manufactured part, including internal cavities.

- Removal of parts from the manufacturing platform once fabricated.

- Removal of support structures.

Finishing processes

- Reduction of surface roughness in order to improve properties such as fatigue, friction and heat exchange while also guaranteeing aesthetics.

- Finishing of parts with intricate geometries where smoothness is critical for industrial applications, e.g. heat exchangers or hydraulic components.

- Heat treatments (solution, ageing, stress relief, etc.) for the parts to achieve their optimum properties or reach a higher density (HIP).

- Protection of parts during their service life, e.g. from corrosion or wear (anodising or plating).

Who is it for?

For the whole coating industry value chain: chemical suppliers, finishing industry, part and component manufacturers, end-users/OEMs.

End users:

Our capabilities and infrastructure

We develop different removal and finishing processes to provide quality, functionality, and aesthetics to AM parts, both metallic and polymeric.

We have an interdisciplinary team with strong skills and extensive experience in different industrial sectors, capable of carrying out cutting-edge research focused on different needs. Our fully equipped laboratories and pilot-plant facilities also allow our solutions to be applied and tested in pre-industrial conditions, including surface preparation and pre-treatment protocols.

- FDM additive manufacturing equipment.

- R&D laboratories for the design, synthesis, and chemical analysis of post-processing formulations.

- Pilot lines for chemical, electrochemical and electropolishing treatments.

- Blasting equipment.

- Vibratory finishing equipment.

- Furnace heat treatments under inert atmosphere.

- Characterisation equipment, including:

- 2D roughness measurement.

- 3D confocal microscopy.

- Bridge coordinate measuring machine.

- Others: morphology, composition, structure, aesthetics, wettability, hardness, scratch resistance, ageing and corrosion, etc.

Any questions?

For more information please contact us:

More information

"*" indicates required fields

Related Patents

Related Patents Get more information

Get more information Visit our Youtube Channel

Visit our Youtube Channel