HYDROGEN TECHNOLOGIES

Renewable hydrogen plays a key role in the energy transition towards a low-emission global economy, as well as in the decarbonization of various industrial sectors. In this context, CIDETEC Surface Engineering works to improve the viability of hydrogen technologies through innovative solutions based on surface engineering.

What do we offer?

With more than 25 years of experience, at CIDETEC we have developed innovative hydrogen technologies, focusing on efficiency, scalability, environmental impact (sustainability), and safety.

Hydrogen Production

We develop advanced solutions to improve hydrogen production through water electrolysis, optimizing materials and processes to achieve greater efficiency and cost reduction:

- Advanced electrocatalysts, more efficient and with lower noble metal content for PEM AEM and AE electrolysis.

- Electrodes and assemblies (MEA) for high-efficiency electrolysis.

- Free-standing and binder-free electrodes without platinum group metals (PGM) for PEM, AEM, and AE electrolysis.

- Validation of materials at laboratory scale to ensure their performance.

- Coatings for bipolar plates.

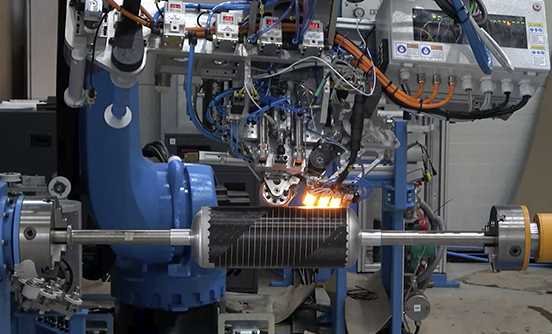

Hydrogen Storage

Safety and durability in hydrogen storage are key to its large-scale deployment. Our solutions include:

- Hydrogen storage tanks (type IV), lightweight and sustainable, based on CIDETEC’s proprietary “3R®” technology.

- 3R® composites for hydrogen storage tanks (high pressure and cryogenic).

Hydrogen Transport and Distribution

Hydrogen transport requires minimizing leaks and avoiding material damage. At CIDETEC we offer:

- Metallic and ceramic coatings that act as barriers against hydrogen permeation.

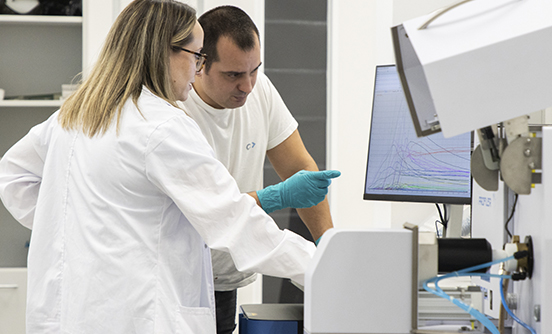

- Characterization of coatings and materials to evaluate their resistance to embrittlement and permeability.

- Advanced analysis with GDOES technique, which allows measuring hydrogen penetration in materials.

- Wear evaluation with in-situ H2 generation.

Use of hydrogen in fuel cells

To optimize fuel cell efficiency, we develop advanced technologies that include:

- Innovative electrocatalysts and electrodes (MEAs) for PEMFC, with lower use of precious metals.

- Coatings for bipolar plates, increasing their resistance to corrosion in hostile environments.

- Evaluation of materials in fuel cells, ensuring their durability and performance.

For Whom?

We offer solutions for the entire hydrogen value chain: from production, with emphasis on acidic and alkaline electrolysis, through storage and transport, to final industrial uses or for electricity production through fuel cells:

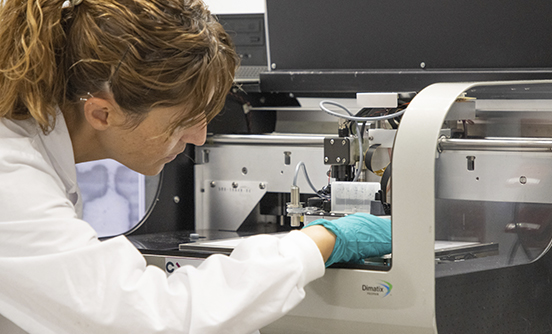

Our capabilities and infrastructure

CIDETEC Surface Engineering has fully equipped laboratories as well as pilot plants that allow us to apply and test our solutions under pre-industrial conditions.

Synthesis laboratory

Physical characterization laboratory

Electrochemical characterization laboratory

Any questions?

For more information please contact us:

More information

"*" indicates required fields

Patentes relacionadas

Patentes relacionadas Más información

Más información Visita el canal de Youtube

Visita el canal de Youtube